Unlocking Hidden Atomic Patterns in Metal Alloys: A Breakthrough in Manufacturing

Traditionally, the processing of metal alloys has been believed to result in the random mixing of atoms from different elements. However, groundbreaking research conducted by experts from the Massachusetts Institute of Technology (MIT) challenges this conventional wisdom by revealing hidden atomic patterns that persist even after intense manufacturing processes.

The recent lab studies have identified subtle patterns in metal alloys that can be manipulated to enhance properties such as mechanical strength, durability, and radiation tolerance. This new research sheds light on how these patterns emerge and endure, offering exciting possibilities for controlling metal properties during manufacturing.

The team at MIT conducted detailed computer simulations focusing on an alloy of chromium, cobalt, and nickel (CrCoNi) to observe the behavior of atoms during rapid cooling and extensive stretching – common processes in manufacturing. What they discovered was both unexpected and groundbreaking.

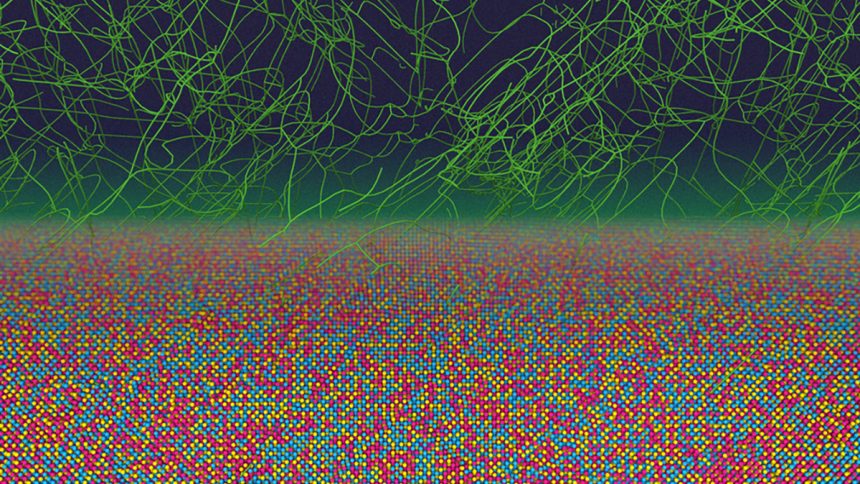

Not only did they observe familiar atomic patterns that defied the rapid deformations, but they also uncovered entirely new patterns termed as “far-from-equilibrium states.” These states were found to be sustained by defects or dislocations in the crystal structure of metals, acting as atomic-level scribbles that help the metal withstand external strain.

Contrary to previous assumptions, the research showed that atoms in metal alloys exhibit some predictability in their movement even after deformations and defect formation. This non-equilibrium state, driven by the preferences of defects for low-energy pathways, presents a new avenue for exploring the properties of metal alloys.

These findings imply that manufacturing processes play a crucial role in creating unique atomic patterns in metal alloys, ultimately influencing their properties. This opens up possibilities for fine-tuning metal properties for applications ranging from nuclear reactors to spacecraft, based on the intrinsic behavior of atoms in these materials.

Published in Nature Communications, this research highlights the intricate nature of metal alloys and the potential for harnessing hidden atomic patterns to revolutionize manufacturing processes. As MIT materials scientist Rodrigo Freitas aptly puts it, “You can never completely randomize the atoms in a metal. The fact that you cannot completely mix something together, people didn’t see that coming.”