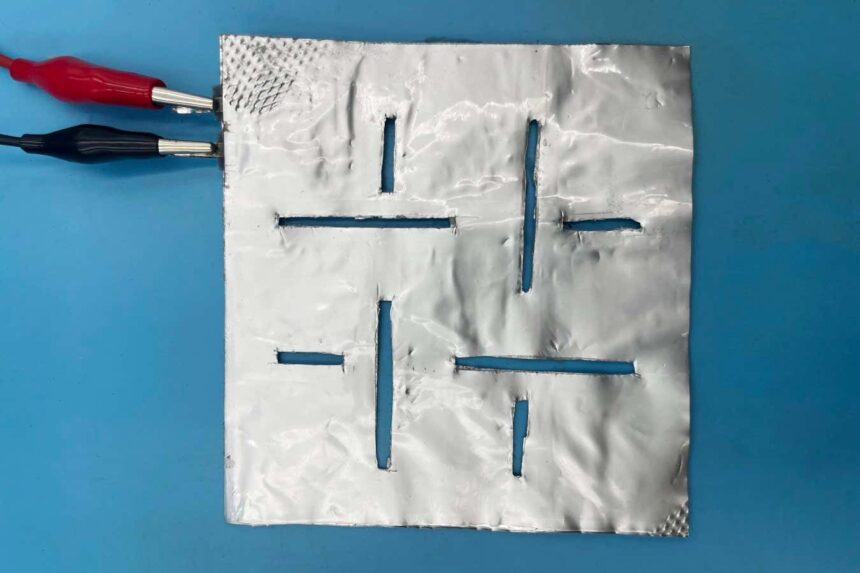

A battery pouch with rectangular holes

Liangbing Hu/Teng Li

A groundbreaking innovation in battery technology has paved the way for a new era of wearable electronic devices. A team of researchers has developed a stretchy and flexible battery pouch with strategically placed holes, making it more breathable than cotton. This breakthrough could revolutionize the design of wearable sports or fitness devices that can be seamlessly integrated into clothing.

Lead researcher, Lin Xu from Yale University, highlights the significance of this development for athletes and individuals who rely on electronic devices for extended periods. These include smart clothing for fitness tracking, medical monitoring devices, and other applications that demand both comfort and reliable performance.

The key to this innovative battery design lies in the pattern of long, rectangular holes strategically placed in a pouch cell battery. Through simulations, the researchers demonstrated that this unique array of holes allows the battery to be stretched or folded 180 degrees without tearing, surpassing alternative hole patterns involving squares or circles.

Xu explains the challenges faced in balancing mechanical stretchability with electrical performance to maintain high energy density in the battery. The team conducted extensive testing, including stretching by 10% and folding experiments, which showed that the holey battery design could withstand physical stress and continue to power LED light bulbs.

Further testing revealed that the holey battery design was twice as breathable as cotton, making it ideal for wearable applications. In a practical demonstration, the researchers integrated the battery into a lab coat and tested its performance during physical exercise. The battery’s ability to dissipate heat quickly through its holes proved beneficial in preventing discomfort and sweat accumulation on the wearer’s skin.

While the battery shows promising results, the researchers acknowledge the need for more wear-and-tear testing. Future plans involve testing the battery’s performance in commercial health monitoring devices and sports gear. Additionally, efforts are underway to scale up production and ensure consistent hole placement and sealing to avoid leaks or short circuits in the battery pouch.

Topics: