The Sustainability of Ancient Roman Concrete: Lessons for Modern Cement

The ancient Romans were master builders, constructing structures that have stood the test of time for thousands of years. One of their key innovations was the development of sustainable concrete that has intrigued researchers to this day.

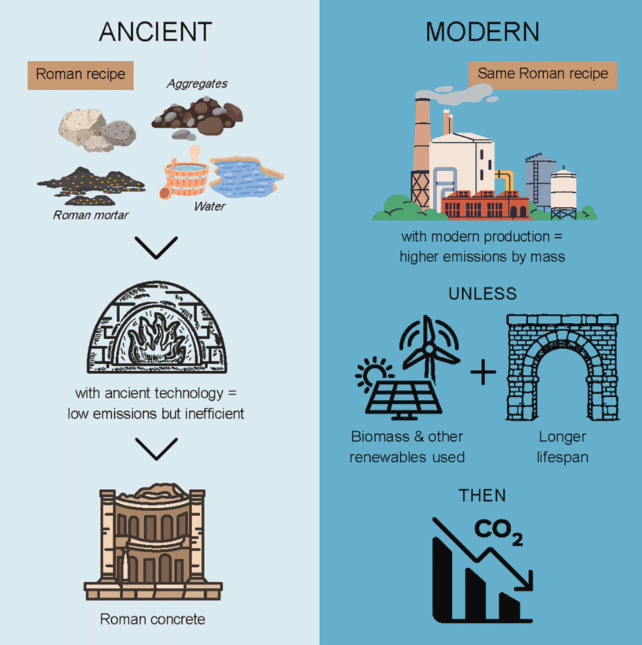

A recent study has delved into the raw materials and energy requirements of Roman concrete, offering insights that could enhance modern cement production. Surprisingly, the analysis revealed that Roman concrete production involves more water and greenhouse gas emissions compared to contemporary Portland cement.

However, the longevity of Roman concrete structures could outweigh these initial environmental costs. Unlike modern cement that often needs frequent repairs or replacements, Roman concrete has proven durability over millennia.

Key Findings:

- Roman concrete formulations would need to outlast modern cement by at least 41 percent for buildings to have similar cumulative emissions.

- For shorter-lived structures like streets and highways, Roman concrete would need to endure at least 29 percent longer.

“By considering the service life of concrete structures, we begin to see the sustainability benefits of Roman concrete,” says lead author Daniela Martinez from the University of the North in Columbia. “Integrating ancient Roman strategies with modern innovations could pave the way for a more sustainable built environment.”

Modern concrete often incorporates steel reinforcement, which can lead to degradation as the steel corrodes. In contrast, Roman concrete exhibits self-healing properties, where cracks are naturally filled when exposed to water, contributing to its long-lasting resilience.

Author and engineer Paulo Monteiro from the University of California, Berkeley, emphasizes the need for cautious comparisons between modern and Roman concrete due to the impact of steel reinforcement on structural integrity.

While longer-lasting concrete structures may offset the need for new materials, Roman cement production methods offer additional environmental advantages. Both Roman and modern cement rely on quicklime derived from limestone, but Roman concrete incorporates locally available volcanic rocks instead of gypsum.

Roman concrete production also generates fewer harmful air pollutants, as the limestone is heated using biomass fuels like oak and fir wood rather than fossil fuels.

Recent models suggest that adopting Roman cement techniques could reduce nitrogen oxide and sulfur oxide emissions by up to 98 percent compared to conventional methods.

“Utilizing biomass and alternative fuels in cement kilns could be a more effective approach to reducing carbon emissions in modern cement production than simply replicating Roman concrete formulations,” notes Martinez.

Concrete is a ubiquitous material, second only to water in global usage. However, its production contributes significantly to carbon emissions, with cement manufacturing accounting for about 8 percent of global anthropogenic carbon emissions.

According to materials scientist Narayanan Neithalath from Arizona State University, addressing cement-related emissions is crucial for meeting climate targets. He highlights the urgent need to reduce cement emissions by over 20 percent within the next decade to align with the goals of the Paris Agreement.

“Studying ancient Roman concrete provides valuable insights that could help us tackle the pressing challenge of reducing carbon emissions in cement production,” concludes Neithalath.

The study was published in iScience.