The nuclear industry is currently experiencing a resurgence, with old plants being revamped and startups receiving substantial investments. In the final weeks of 2025, nuclear startups managed to secure a staggering $1.1 billion in funding, largely due to investor confidence in the potential success of smaller nuclear reactors.

Traditional nuclear reactors are known for their massive size and complexity. For instance, the Vogtle 3 and 4 reactors in Georgia are colossal structures powered by fuel assemblies 14 feet tall, generating over 1 gigawatt of electricity each. However, these projects faced significant delays and cost overruns, highlighting the challenges of large-scale nuclear infrastructure.

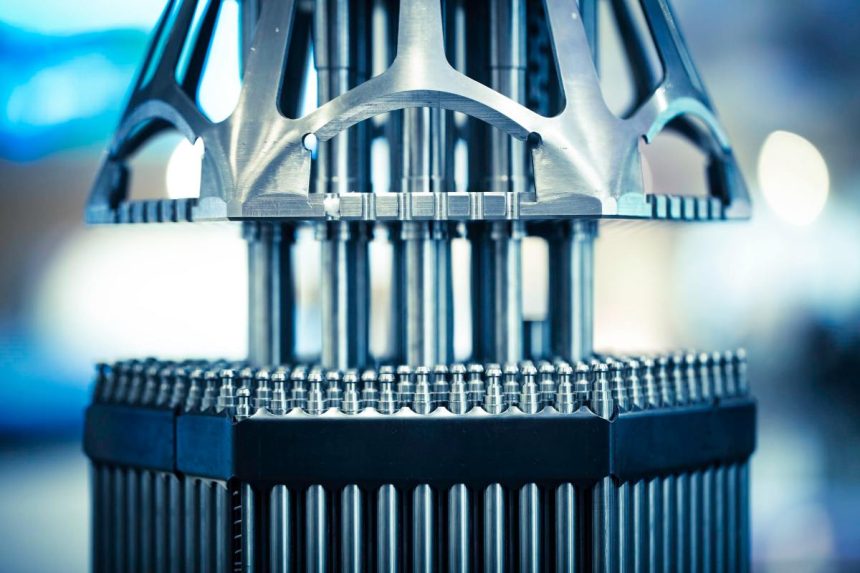

In contrast, the new wave of nuclear startups is focusing on developing smaller reactors to overcome these issues. By reducing the size of the reactor, companies believe they can streamline production using mass manufacturing techniques, leading to cost savings and improved efficiency over time. The exact extent of these benefits is still under study, but startups are banking on significant advantages.

Nevertheless, manufacturing small nuclear reactors presents its own set of challenges. Unlike industries like automotive, where the U.S. has established expertise, the nuclear sector faces barriers due to a lack of domestic manufacturing capabilities. Many essential materials are sourced from overseas, highlighting the need for investment in local production infrastructure.

Milo Werner, a seasoned manufacturing expert and investor, emphasizes the importance of building a robust manufacturing ecosystem to support nuclear startups. While capital may not be a major constraint for these companies, the shortage of skilled manufacturing personnel poses a significant hurdle. With decades of offshoring, the U.S. lacks experienced professionals in factory construction and operations, hindering the industry’s growth.

Despite these challenges, there is cause for optimism. Startups are increasingly integrating manufacturing processes closer to their technical teams, facilitating rapid iterations and improvements. Embracing modularity and scalability is crucial for success, allowing companies to start small and gradually increase production volumes while refining their manufacturing processes.

While the benefits of mass manufacturing may take time to materialize, the long-term potential for cost reductions and efficiency gains is substantial. By investing in a skilled workforce and embracing innovative manufacturing practices, the nuclear industry is poised for a renaissance driven by smaller, more agile reactors.